Any useful engineering methodology must incorporate an unambiguous specification of the system of interest, because there are many different stakeholders with many different questions about the system, from design to planning, to control. Clearly distinguishing models of the artifact from analysis models used to answer questions about the artifact is standard practice in structural engineering, circuit engineering, aerospace systems engineering, etc. However, in the extant literature on DELS, this formal specification of the system per se does not exist. In manufacturing, for example, two of the leading textbooks, Factory Physics (Hopp and Spearman 2011) and Manufacturing Systems Modeling and Analysis (Curry and Feldman 2010) provide a number of analysis models of manufacturing systems, but never provide a formal definition of the manufacturing system itself. In warehousing, a widely used e-text, Warehouse & Distribution Science (Bartholdi and Hackman 2011) provides verbal descriptions and figures to describe warehouses informally, but all of the formal models are analysis models. In supply chains, a textbook by leading researchers in the field, Designing and Managing the Supply Chain (Simchi-Levi, Kaminsky, and Simchi-Levi 2008) focuses intently on analyzing supply chains, without providing a formal specification of the analyzed system per se.

Why is this important? In DELS, as in any large, interesting engineered system, there are multiple concerns, or stakeholders. To take but one example, in designing a fulfillment system, there clearly is concern to make the item retrieval process efficient, because much of it is likely to be done by humans, and therefore to be costly. But this concern has a clear interaction with the concern for customer service, where achieving higher service levels generally requires more labor. If there is no meta-model of fulfillment system, then the analysis models developed to support the design decisions will be, in essence, ad hoc expressions of the analyst's conception of the system. Consequently, the analysis methods available to address the two different concerns will be difficult or impossible to make inter-operable, and the design of the fulfillment process will depend on ad hoc analysis integration schemes. This illustration is indicative of the challenges faced across the entire DELS spectrum, namely, existing analytic models generally address a single concern, and they share no common underlying specification of the system of interest, and therefore are difficult or impossible to integrate or make inter-operable.

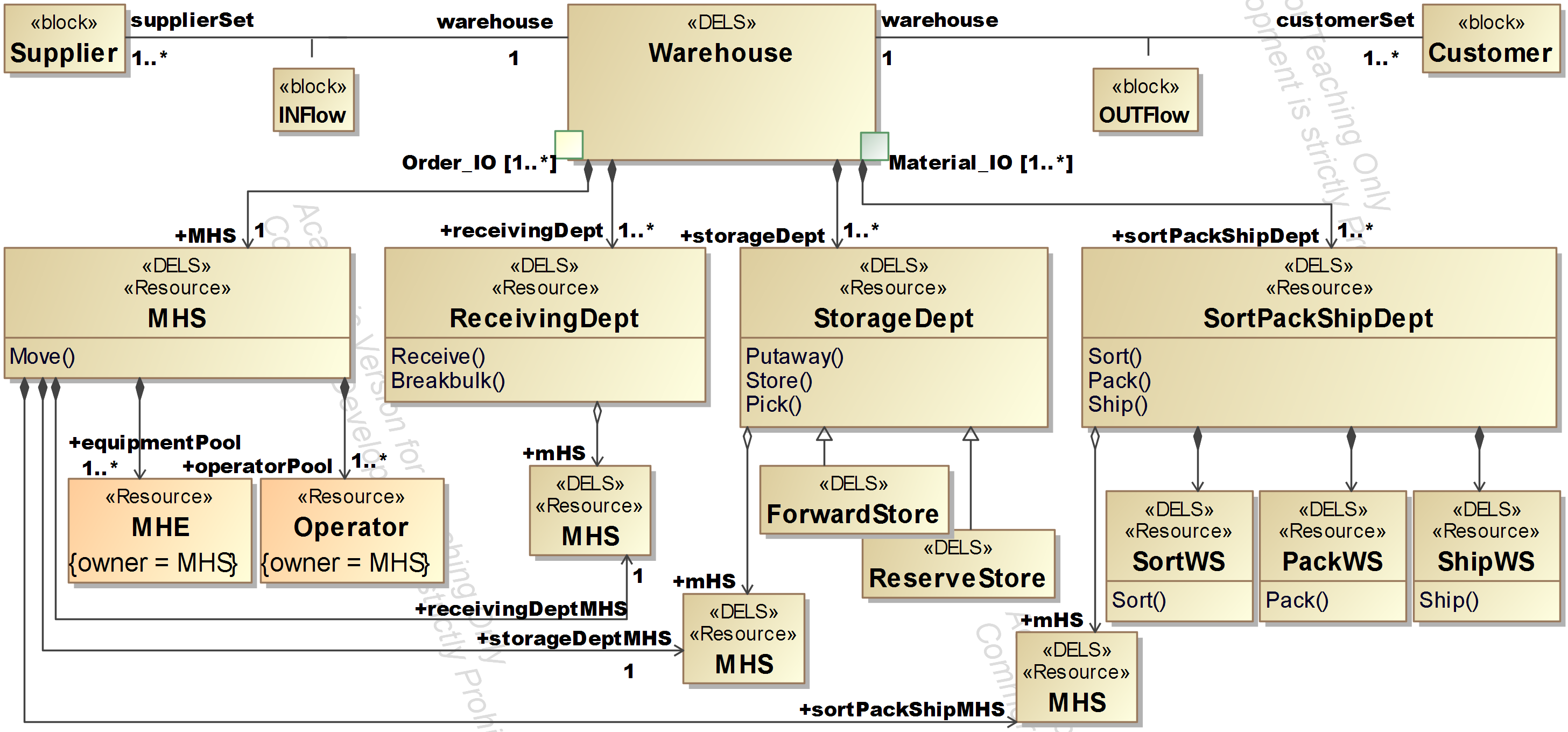

The research i the Keck VFL is unique in seeking to establish a "universal DELS language," i.e., the semantics and syntax, along with patterns of usage, for describing both classes of DELS (all distribution warehouses) and DELS instances (a particular distribution warehouse). We use OMG Systems Modeling Language (SysML) to develop an ontology, both at the abstract level (class of all DELS) and at the concrete level (class of all distribution warehouses, or a specific warehouse).

Modeling principles emerging from the Kec VFL research include:

- the fundamental abstract structure underlying all DELS is the token flow network, where tokens represent the product flowing through the DELS, nodes represent the transformation of the product, and arcs represent flow-enabling connections between processes/resources

- behavior at a node is defined by a process executed by a resource; when the product, process and resource are specified, the behavior is also specified

- control in DELS does not impact behavior, rather it determines the product flow by answer five canonical control questions:

- should a flow object be accepted into the system (admission)

- when should an accepted flow object by processed (sequencing/scheduling)

- what resource should be assigned to execute a process on a flow object

- where should a flow object go after processing

- what should be the state of a resource

Currently, Keck VFL research on domain modeling is focused on operational decision making for planning and control, and particularly on how to integrate planning decisions with control decisions.

Related Publications

Presentations

- ViewA talk that explores the opportunity to harvest 40 years of innovation in product design to enable a new generation of logistics systems decision support.

Conference Papers

- Sprock, Timothy, and Leon F. McGinnis. "A Conceptual Model for Operational Control in Smart Manufacturing Systems." IFAC-PapersOnLine 48.3 (2015): 1865-1869.

- Sprock, Timothy, and Leon F. McGinnis. "Analysis of Functional Architectures for Discrete Event Logistics Systems (DELS)." Procedia Computer Science 44 (2015): 517-526.

- Thiers, G., and L. McGinnis (2013), “A SysML-Based Semantic Reference Model for Design-to-Production Translation,” ISERC 2013, San Juan, Puerto Rico.

- Sprock, T., and L. McGinnis (2013), “An Object-Oriented Implementation of SCOR,” ISERC 2013, San Juan, Puerto Rico.